This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Preparing Your Packaging Data for EPR Compliance

Posted on February 18, 2026 by Neva Modric

#Circular System #Corporate Governance #Corporate Responsibility #Corporate Sustainability #EPR #ESG #ESG Issues #Supply Chain #Sustainability Reporting #Uncategorized

By Neva Modric, Sustainability Analyst, G&A Institute

Compliance with Extended Producer Responsibility (EPR) packaging laws requires several steps, beginning with a scoping exercise to determine the packaging materials a company is responsible for, and to which U.S. states it must report. After this scoping exercise, a company faces its next challenge: the accurate and complete reporting of packaging data. This may be the most significant operational challenge of EPR packaging compliance, simply because companies have likely never had to track, collect, or report such data before.

New to our EPR blog series? Get up to speed with our introductory blog on the topic, our FAQ on how to comply, and our detailed resource paper.

What Data is Expected

EPR packaging laws require detailed information from covered producers about the materials introduced into the market, including:

- Category of each covered packaging material, according to each state’s classification standards (e.g., corrugated cardboard, PET lid, aluminum container)

- Packaging components (primary structure and any linings, adhesives, and other components)

- Weight per unit of packaging material sold, by category

- Volume of packaging material shipped to each state with EPR packaging laws

Why Accurate Data is Important

Because EPR laws are enacted at the state level, reporting requirements differ across states. Companies selling products nationally may therefore need to track and report packaging data for multiple states with varying definitions, thresholds, and timelines.

We recommend that each company develop a centralized approach to managing packaging data. This will reduce complexity now and as more states adopt EPR laws for packaging. Accurate data collection by companies is critical for the following reasons:

- Confidence in compliance – Accurate collection is required for proper scoping and reporting of data, which may ease internal anxiety about non-compliance while also supporting readiness for any more rigorous data requirements in the future

- Accountability and transparency – Reliable data from a covered producer will support trust and credible communication between the company and regulators, investors, customers, and other stakeholders

- Successful program funding – Because PRO fees are based on reported information about the type and amount of packaging introduced into each state, reliable data is required for PROs to calculate necessary fees to fund state programs

Curious about U.S. state-specific requirements, as well as past and upcoming producer reporting deadlines? Download our resource paper.

Options for Calculating and Reporting Packaging Materials

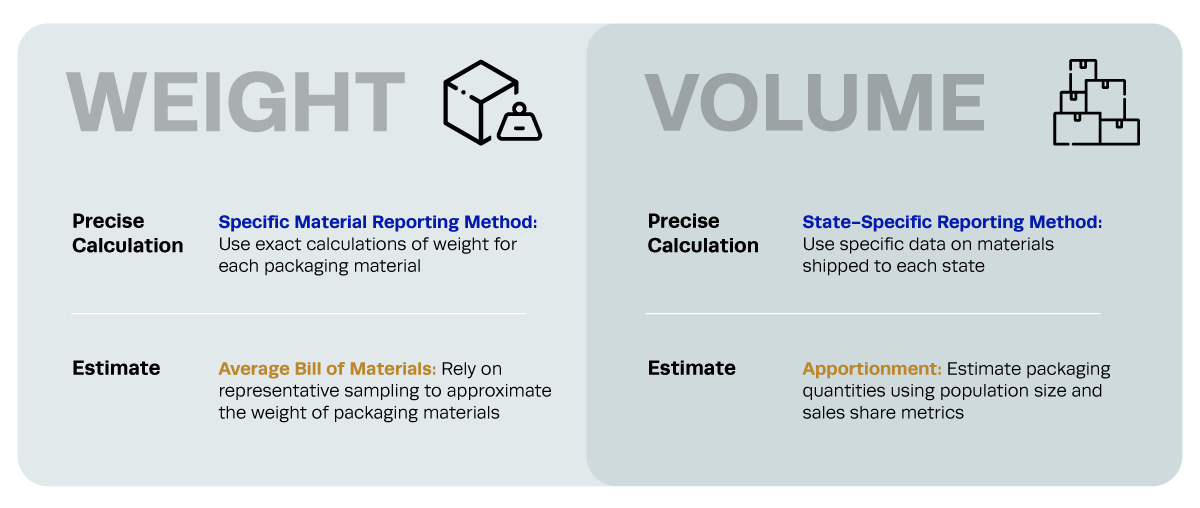

To comply with EPR packaging requirements, producers are expected to report the weight of their packaging materials per unit, as well as the volume of packaging materials shipped to each state. Within those requirements, there are two calculation methods available to producers:

Recommended Data Collection Practices for Producers

Conduct a Comprehensive Review of Your Packaging Materials

Begin by cataloging all packaging materials used across your product lines. This includes:

- Primary packaging

- Secondary packaging

- Tertiary packaging, as applicable

Collaborate with internal teams, suppliers, and contract manufacturers to source relevant data. Many companies discover that packaging information is scattered across procurement, operations, and product management functions.

Prioritize Precise Calculation Methods

G&A recommends that companies aim to use actual data (the “specific” reporting methods shown above) instead of estimated data for reporting packaging weight and packaging volume. These approaches will provide greater accuracy when calculating fees and avoid overestimation to ensure companies pay only what is required.

More precise methods also enable companies to take advantage of modulation incentives. Modulated fees are adjusted fees that can be reduced based on the environmental characteristics of the packaging—such as recyclability, material type, or recycled content. Modulated fees aim to incentivize more sustainable packaging choices.

While estimated data may be easier to achieve in the short-term, producers that rely on estimation risk overpayment of fees and may ultimately need to develop more robust data collection systems in the future.

Employ Consistency

Create a methodology for quantifying packaging materials that can produce consistent results over time. This will allow your company to reduce compliance costs by leveraging modulated fees.

Key considerations include:

- Data methodologies: Establish consistent weight calculations in line with state requirements and ensure all methodologies are tracked, because Producer Responsibility Organizations (PROs) may conduct report validations.1

See the first blog post in our packaging EPR series for more information on PROs.

- Material classification: Align your material categories with each state’s reporting requirements. Different states may classify materials differently.2

- Allocation methods: For products sold in multiple states, develop an approach for determining packaging volumes shipped to each state. Consider which of the methods listed above you would like to utilize, but keep in mind that accuracy will be rewarded, through modulated fees, and may become mandatory in the future.1

Partner with Suppliers

Many companies rely on suppliers or contract manufacturers for packaging specifications. Building EPR data collection into supplier relationships is essential.

Consider asking suppliers to provide:

- Detailed specifications for packaging they provide, including packaging components and material types

- Information on recyclability and recycled content of packaging materials for modulated fees

- Updates when packaging materials or compositions change

How Can G&A Help Companies Collect Data for Packaging EPR Laws?

EPR compliance is becoming a standard business requirement for companies placing packaged goods on the U.S. market, and meeting those obligations depends heavily on the quality of data.

For companies that have already identified their EPR reporting obligations, G&A helps to develop packaging data management systems, fill data gaps, and submit supply reports. Our approach helps ensure packaging data is accurate, repeatable, and scalable as packaging EPR legislation continues to evolve.

Schedule a call to learn how G&A can help your company build a practical EPR packaging data collection process, or get our help at an earlier stage with a scoping exercise and compliance plan.

References:

- Circular Action Alliance: Preparing to Report Your Supply Data

- Oregon’s material classification list can be found here. Colorado’s material classification list can be found here.

ABOUT NEVA MODRIC

ABOUT NEVA MODRIC

Sustainability Analyst, G&A Institute

Neva Modric is a Sustainability Analyst at Governance & Accountability Institute. Her role includes conducting research to support client engagements, assisting with double materiality assessments, developing sustainability reports, analyzing ESG data, and providing general sustainability consulting. She is passionate about helping companies drive positive, sustainable impact that benefits both people and the environment.